騒々しい発電機、有毒ガス、産業現場での絶え間ない燃料補給の手間にうんざりしていませんか?このような従来の電源は、解決するよりも多くの問題を引き起こすことが多いのです。信頼性の高いクリーンな電力を求める声は絶えません。

発電機はこれまで標準的なものだったが、エネルギー貯蔵は長期的なコスト、環境への影響、運用の容易さにおいて、説得力のある利点を提供すると私は思う。最良の選択は特定の用途によって異なるが、蓄電の優位性はますます高まっている。

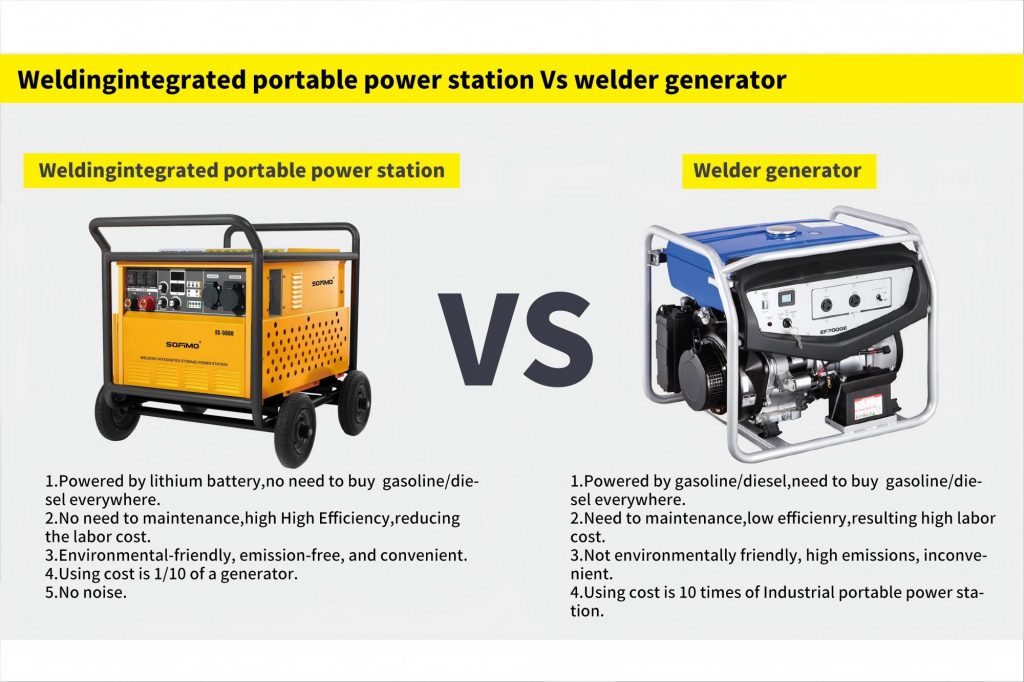

適切な電源の選択は、プロジェクトの効率、予算、安全性に大きく影響します。この2つの技術を重要な要素で直接比較してみましょう。

長期的なコストの違いは? 産業用ポータブル発電所 と燃料発電機?

発電機の購入やレンタルは、初期費用は安いように思えるが、その後、燃料代や修理代が転がり込んでくる。このような隠れたコストは、すぐに積み重なります。私は常に、最初の値札だけでなく、トータルコストを分析します。

エネルギー貯蔵は通常、初期コストは高いが、総所有コストが低いため、長期的には経済的であることを知っている。これは、燃料費が不要になり、メンテナンスの必要性が大幅に減ることに起因する。

電力ソリューションを比較する際、購入価格だけを見るのは誤解を招く。燃料発電機は当初は安価に見えることが多いが、運用コストはすぐにかさむ。エネルギー貯蔵システムは、初期投資は高くなる可能性がありますが、耐用年数にわたって大幅な節約が可能です。総所有コスト(TCO)を計算することで、より明確なイメージが得られます。

初期費用

燃料発電機:一般的に、特に大きな出力(kW)を提供する基本的なモデルの場合、購入価格やレンタル料が安い。

産業用ポータブル発電所:特にエネルギー容量(kWh)が大きいシステムの場合、初期購入価格が高くなる傾向がある。コストはバッテリー容量に大きく影響される。

燃料費

燃料発電機:これは継続的な大きな出費となる。発電機は運転中、ディーゼルまたはガソリンを消費し続ける。コストは、燃料価格(変動する)、消費率(負荷に依存)、運転時間によって異なります。燃料の運搬や燃料補給のための人件費もかさみます。

産業用ポータブル発電所:燃料費ゼロ。エネルギーは電力網(またはソーラーパネルなどの自然エネルギー)から供給される。充電には費用がかかるが、電気はディーゼルやガソリンよりもエネルギー単価が大幅に安いことがほとんどだ。充電は多くの場合、電気料金が最も安いオフピーク時にスケジュールすることができる。

メンテナンス費用

燃料発電機:定期的な予防保守が必要です。これには、オイル交換、エアフィルタの交換、燃料フィルタの交換、スパークプラグの交換(ガソリンモデルの場合)、および時間の経過に伴うより複雑なエンジン整備が含まれる。エンジンには磨耗しやすい可動部品が多く、修理費用やダウンタイムの増加につながります。

産業用ポータブル発電所:必要なメンテナンスは最小限。液体を交換したり、フィルターを交換したり、スパークプラグを交換したりする必要はありません。メンテナンスは通常、ユニットを清潔に保ち、接続をチェックし、該当する場合は時々ソフトウェアを更新します。可動部品が少ないということは、信頼性が非常に高く、故障が少ないということです。

運用コスト(騒音/排出ガス)

燃料発電機:騒音は、労働時間の制限、潜在的な罰金、または騒音緩和対策の必要性につながり、間接的なコストを増加させる。排ガスは、屋内での使用を妨げたり、費用のかかる換気システムを必要としたりする。

産業用ポータブル発電所:静かで排気ガスのない運転により、これらのコストを完全に回避できます。屋内や騒音規制中でも問題なく使用できます。

寿命と交換

燃料発電機:寿命は、使用パターンとメンテナンスの質に大きく左右される。酷使されるとエンジンは比較的早く消耗し、高価なオーバーホールや交換が必要になる。

産業用ポータブルパワーステーション:バッテリーの寿命は通常、充電サイクル(例:2000~5000サイクル以上)および暦年(例:10年以上)で測定され、多くの場合、最終的にかなりの容量(例:80%)を保持します。バッテリーが劣化する一方で、高品質のシステムは、主要なコンポーネントの交換が必要になる前に、使用頻度の高い発電機よりも長持ちすることがよくあります。

以下は、仮想的な寿命におけるTCOの比較である:

| コスト係数 | 燃料発電機(イメージ) | 産業用ポータブル発電所(イラスト) | 主な違い |

| 初期費用 | $3,000 | $8,000 | ESSの初期費用が高い |

| 燃料費(5年間) | $15,000 | $1,500(電気代) | ESSによる大幅な燃料節約 |

| メンテナンス(5年) | $2,500 | $250 | メンテナンスの大幅な節約 |

| 騒音/ヒュームの問題 | 想定されるコスト | $0 | 発電機特有の問題を回避 |

| 合計(5年間) | $20,500 + 想定される費用 | $9,750 | ESSの方が長期的には安い |

(注:これは簡易見積もりであり、実際の費用は大きく異なる)

全ライフサイクルを考慮すると、燃料費が不要になり、メンテナンスが軽減されるため、初期投資が高くなるにもかかわらず、エネルギー貯蔵の方が経済的な選択になることが多い。

どのように 産業用ポータブル発電所 燃料発電機と環境負荷の比較?

発電機の運転は、絶え間ない騒音、臭いガス、温室効果ガスの排出に対処することを意味します。これらは作業現場やより広い環境に影響を与える。私は、よりクリーンな電源を選択することが、責任ある事業運営にとってますます重要になってきていると考えている。

エネルギー貯蔵は、運転中の環境への影響が非常に少ない。私は、燃料発電機の汚染と騒音に比べ、現場での大気排出がゼロであることと、運転音が静かであることを強調している。

発電の環境フットプリントは、今日、多くのビジネスやプロジェクトにとって重要な考慮事項である。燃料発電機とエネルギー貯蔵システムは、地域環境と地球環境に与える影響が根本的に異なります。

大気排出

燃料発電機:化石燃料(ディーゼルまたはガソリン)を燃やし、使用時に大気中に汚染物質を直接放出する。主な排出物は以下の通り:

温室効果ガス(GHG):気候変動の原因となる二酸化炭素(CO2)。

窒素酸化物(NOx):スモッグ、酸性雨、呼吸器疾患の原因となる。

粒子状物質(PM2.5):呼吸器や循環器の健康に有害な微粒子。

一酸化炭素(CO):有毒ガスで、密閉された空間では特に危険。

揮発性有機化合物(VOC):スモッグ形成に寄与する。

産業用ポータブル発電所:運転中の直接的な大気排出はゼロ。環境への影響は、主に製造工程と充電に使用する電力源に関連します。再生可能エネルギー(太陽光、風力)で充電する場合、運用時の二酸化炭素排出量は実質的にゼロです。

騒音公害

燃料発電機:70~90デシベルを超えることが多い。作業現場を混乱させ、近隣の居住者や住民に迷惑をかけ、騒音条例に違反することもある。

産業用ポータブル発電所:ほぼ無音で作動します。通常、騒音は内部の小型冷却ファンから発生するものだけで、通常の会話やオフィス環境よりも静かです(50 dB以下)。

燃料取扱のリスク

燃料発電機:可燃性液体(ディーゼルまたはガソリン)を保管し、取り扱う必要がある。これには以下のリスクがある:

流出:土壌および水を汚染する。

漏れ:燃料蒸気の放出。

火災の危険:特に給油中。

産業用ポータブル発電所:燃料取扱いのリスクを排除。可燃性液体の保管や移送が不要です。

カーボンフットプリント

燃料発電機:燃料の燃焼による直接的なCO2排出のため、運転時のカーボンフットプリントが大きい。

産業用ポータブル発電所:二酸化炭素排出量は充電源によって異なります。化石燃料による送電網から充電する場合は、間接的なフットプリントが発生する。しかし、再生可能エネルギー源から充電する場合、運用時のフットプリントはごくわずかです。製造プロセス(特にバッテリー)にはカーボンフットプリントがありますが、特に再生可能エネルギーと組み合わせた場合、発電機の排出を避けることでシステムの寿命期間中に相殺されることがよくあります。

環境影響の概要は以下の通り:

| インパクト・カテゴリー | 燃料発電機 | 産業用ポータブル発電所 | メリット |

| 大気排出 | あり(CO2、NOx、PM、CO) | なし(直接) | エネルギー貯蔵 |

| 騒音公害 | 高 (70-90+ dB) | 非常に低い (<50 dB) | エネルギー貯蔵 |

| 燃料流出リスク | はい | なし | エネルギー貯蔵 |

| GHG排出量 | 高い(直接オペレーション) | 低い/なし(運用) | エネルギー貯蔵 |

| 屋内用 | なし(換気が必要) | はい | エネルギー貯蔵 |

環境責任を優先し、地域の大気汚染や騒音公害を最小限に抑え、あるいはカーボンニュートラルを目指すプロジェクトにとって、エネルギー貯蔵は従来の燃料発電機に比べて明確かつ実質的な利点を提供する。

オペレーショナル・アドバンテージとは 産業用ポータブル発電所 燃料ジェネレーターを超えるオファー?

発電機の始動問題、絶え間ない給油停止、大きな騒音、有害なガスへの対処は、混乱を招き、非効率的です。このような煩わしさは仕事を遅らせる。私は、シンプルで確実に使用できる電力ソリューションを好む。

産業用ポータブル・パワー・ステーションは、瞬時の電源オン、屋内での使用に適した静音運転、最小限のメンテナンスの必要性、よりクリーンな出力など、運転上の大きな利点を提供します。これらにより、作業現場がより効率的になることを実感しています。

コストや環境要因だけでなく、エネルギー貯蔵と燃料発電機では、日々の使用感が大きく異なります。産業用ポータブル・パワー・ステーションは、現場での利便性、効率性、安全性を高めるいくつかの運用上の利点を提供します。

瞬時で信頼できるパワー

燃料発電機:始動手順が必要で、(特に寒冷地では)問題となることがある。出力を安定させるのに時間がかかる。機械的な複雑さとメンテナンスの必要性から、信頼性が問題になることがある。燃料切れは突然のシャットダウンを引き起こす。

産業用ポータブルパワーステーション:スイッチひとつで瞬時に電力を供給。ウォームアップ時間はありません。ソリッド・ステート・エレクトロニクスを採用し、可動部品が少ないため、本来の信頼性が非常に高くなっています。充電状態が明確に表示され、予期せぬシャットダウンを防ぎます。

静かな動作と屋内使用

燃料発電機:運転音が大きいため、居住区域の近くや特定の時間帯の使用は制限される。排気ガスにより、屋内での使用は非常に危険であるか、大規模な換気なしでは不可能である。

産業用ポータブルパワーステーション:無音運転により、騒音による迷惑をかけることなく、いつでもどこでも使用できます。排気ガスがないため屋内での使用も安全で、設置場所や用途の柔軟性が飛躍的に向上します。

メンテナンスの必要性を低減

燃料発電機:燃料レベルのチェック、給油、オイルのチェック、フィルターの交換など、定期的な注意が必要。メンテナンスを怠ると故障につながる。

産業用ポータブル・パワー・ステーション:清潔に保ち、充電しておくだけで、日常的なメンテナンスはほとんど必要ありません。そのため、労働時間が短縮され、機器の故障による作業停止の可能性が低くなります。

電力品質

燃料発電機:不安定な電圧や周波数(「ダーティパワー」)を発生させる可能性がある。これは、敏感な電子機器を損傷する可能性がある。

産業用ポータブル発電所:インバーターを利用して、系統電力と同等かそれ以上の、クリーンで安定した正弦波の電力を供給します。これは、コンピュータや最新のツール、繊細な電子機器にダメージを与えることなく電力を供給するのに理想的です。

その他の利点

遠隔モニタリング:最新のESSユニットの多くは、アプリやウェブポータルを介した遠隔監視機能を提供しており、ユーザーは物理的にその場にいなくても、ステータス、充電状態、出力を確認することができる。

拡張性:エネルギー貯蔵システムは、必要に応じて出力やエネルギー容量を増やすために、簡単に並列化できることが多い。

オペレーション上の主な違いをまとめてみよう:

| 運営面 | 燃料発電機 | 産業用ポータブル発電所 | メリット |

| スタートアップ | マニュアル、潜在的な問題、ウォームアップ | インスタント・オン | エネルギー貯蔵 |

| ノイズ | 大声、破壊的 | サイレント | エネルギー貯蔵 |

| 排出ガス/ヒューム | 屋内では危険 | なし | エネルギー貯蔵 |

| 給油 | 頻繁な肉体労働 | 充電(より簡単な場合が多い) | エネルギー貯蔵 |

| メンテナンス | レギュラー、コンプレックス | 最小限 | エネルギー貯蔵 |

| 電力品質 | 不安定になる可能性がある | クリーン、安定(純正弦波) | エネルギー貯蔵 |

| 信頼性 | 低い(可動部品が多い) | より高い | エネルギー貯蔵 |

| 屋内用 | いいえ(または非常に難しい) | はい | エネルギー貯蔵 |

このような運転上の利点は、従来の燃料発電機と比較して、エネルギー貯蔵を使用した場合の利便性の向上、生産性の向上、柔軟性の向上、より安全な作業環境につながる。

どのように 産業用ポータブル発電所 サイズと携帯性に関して燃料発電機と比較するか?

重くてかさばる発電機を引きずりながら現場を回るのは重労働です。また、発電機と燃料缶を置くスペースを確保するのも大変です。スペースの効率的な使用と簡単な運搬が重要な考慮事項であることは承知しています。

産業用ポータブル・パワー・ステーションは、特に小型から中型のユニットにおいて、より優れた電力密度を提供することが多く、よりコンパクトな設計につながります。大容量ユニットは依然として重いが、その柔軟なフォーム・ファクターは携帯性を向上させる。

電源の物理的なサイズと重量は、現場での運搬、配置、取り扱いのしやすさに直接影響する。燃料発電機もエネルギー貯蔵システムも様々なサイズがありますが、その基礎となる技術によって可搬性の特性に違いが生じます。

エネルギー密度と重量

燃料発電機:エンジンと燃料タンクを組み合わせたもの。特に大型のディーゼル・モデルは、その重量が大きい。燃料そのものはエネルギー密度が高いが、エンジンと発電機の部品は、連続出力に対してかなりの嵩と重量を加える。

産業用ポータブルパワーステーション:バッテリーに頼る最新のリチウムイオン電池は、高いエネルギー密度(単位重量または単位体積あたりに蓄えられるエネルギー量)を提供します。つまり、ESSは多くの場合 蓄積エネルギー (kWh)に比べて小型・軽量化されている。 ランニングパワーシステム (エンジン+燃料タンク)の発電機を同じ時間稼働させることができる。しかし、非常に高い 出力 (kW)であっても、発電機のエンジンは、ESSに必要な同等のパワーエレクトロニクスやバッテリーアレイよりも軽いかもしれない。この比較は、ピーク電力(kW)と総蓄積エネルギー(kWh)のどちらを優先するかによって大きく異なる。

フォームファクターとデザイン

燃料発電機:一般的に、エンジン、オルタネーター、燃料タンク、保護フレームによって、ある程度決まったフォームファクターを持つ。箱型や檻のような構造をしていることが多い。

産業用ポータブル発電所より柔軟な設計が可能です。バッテリーと電子機器は様々な構成で配置できます。ユニットは、積み重ね可能なように設計したり、(多くのソフィモモデルのように)車輪付きカートに組み込んだり、あるいは車両やコンテナ内に搭載することもできます。この適応性により、狭いスペースへの組み込みや建物内での輸送が容易になります。

燃料タンク不要

燃料発電機:本体と、燃料缶を安全に保管するための別のスペースが必要。

産業用ポータブル発電所:自己完結型です。燃料貯蔵のためのスペースを追加する必要がないため、ロジスティクスが簡素化され、現場での全体的な設置面積が削減されます。

移植性の比較要素

小型ポータブル・ユニット(3kW未満など):ポータブルバッテリーパワーステーションは、同じようなランタイム能力を持つ発電機(必要な燃料を考慮した場合)よりも、かなり軽量でコンパクトであることが多い。多くの場合、ハンドルや車輪が内蔵されており、一人で簡単に移動できる。

中型機(例:3kW~10kW):重量の比較が近くなる。この範囲の発電機は重いが一般的である。ESSユニットは、要求されるkWh容量によっては、同じような重量か少し重いかもしれないが、多くの場合、操縦性のために優れたフォームファクター(車輪付きカートなど)を持っている。

大型ユニット(例:> 10kW):どちらの選択肢も重くなり、通常、輸送には機械(フォークリフト、クレーン)またはトレーラーが必要になる。ESSユニットは、大型発電機と同様、コンテナ型かスキッドマウント型になる可能性がある。主な違いは、ESSのための現場でのバルク燃料貯蔵が必要ないことである。

まとめると、どちらの技術も大容量では軽量ではないが、エネルギー貯蔵は、より優れたエネルギー密度(特に長時間の運転)、より柔軟なフォームファクター、現場での燃料の必要性を完全に排除することなどにより、可搬性で優位に立つことが多い。

エネルギー貯蔵は、発電機と比較して、長期的なコストの削減、ゼロ・オンサイト排出、静音運転、使いやすさの向上など、明確なメリットを提供します。必要な場合は、バッテリ式溶接機の生産と配送で20年の経験を持つ私たちにご連絡ください。